Key Benefits of Implementing Anti-Foam Control Solutions in Manufacturing Processes

The implementation of anti-foam control solutions in manufacturing processes offers a calculated advantage that qualities cautious factor to consider. By attending to concerns associated to foam formation, manufacturers can dramatically improve production performance, improve product top quality, and decrease functional prices.

Improved Manufacturing Performance

In manufacturing processes, foam can considerably impede production performance by blocking machinery and disrupting workflows. The visibility of foam typically results in equipment malfunctions, requiring unscheduled maintenance and downtime that can badly influence manufacturing timelines. When bubbles create in fluids, they can create blockages in pumps, pipes, and other essential parts, causing irregular item circulation and enhanced functional expenses.

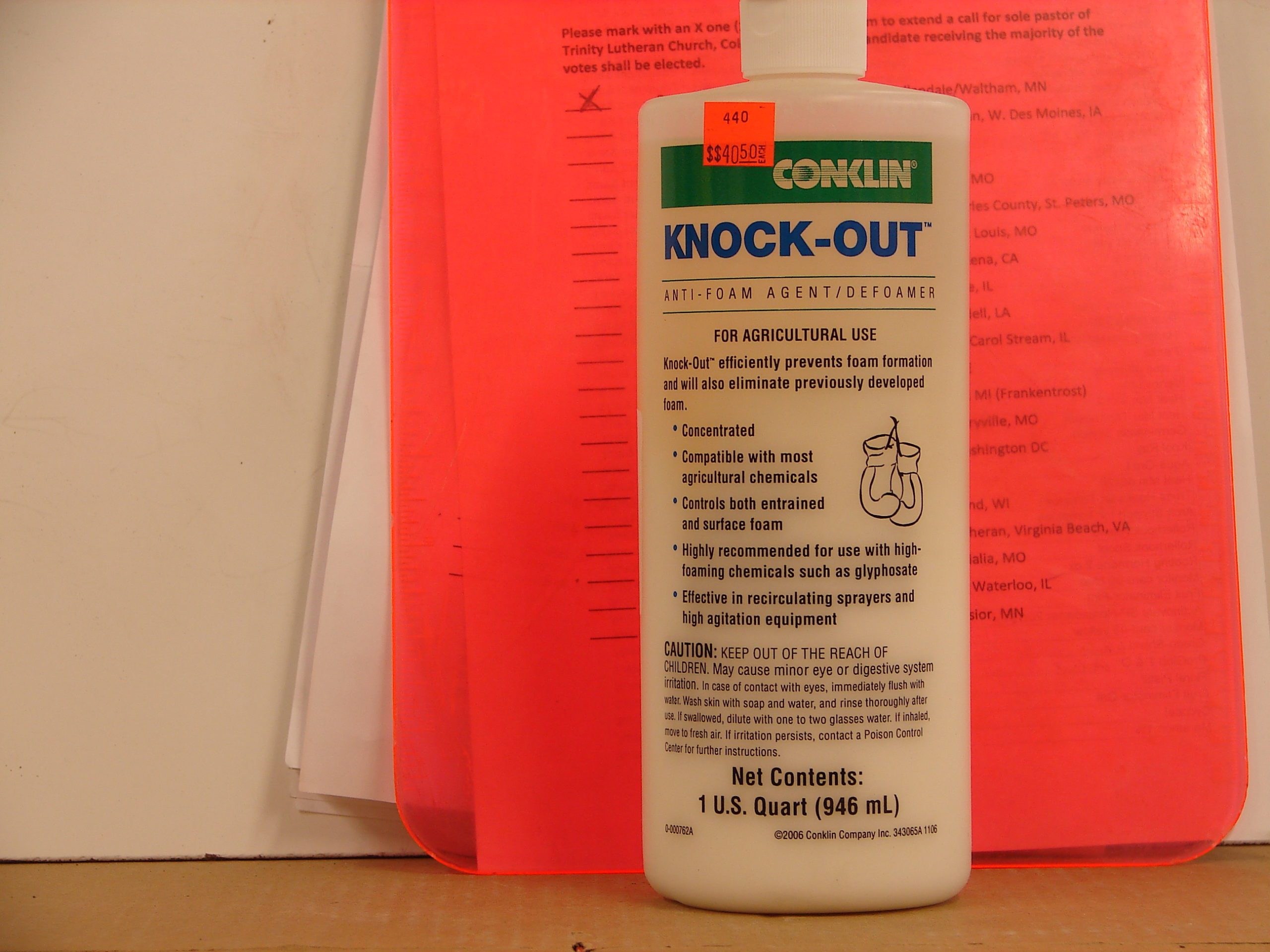

Executing anti-foam control services is essential for mitigating these issues - Anti-Foam Control Solutions. These solutions function by lowering foam formation, guaranteeing smoother procedures and decreasing the threat of machinery obstruction. By maintaining optimal liquid dynamics, producers can enhance throughput and minimize the regularity of devices maintenance, inevitably enhancing the overall effectiveness of the assembly line

Additionally, with minimized downtime, workers can concentrate on other vital tasks, better enhancing procedures. Making use of anti-foam agents not just addresses immediate manufacturing obstacles but additionally promotes a more secure production environment. Consequently, this adds to better source monitoring and price savings, strengthening the importance of purchasing effective foam control techniques as a way to boost manufacturing performance in manufacturing settings.

Improved Item Quality

Foam in producing procedures can compromise item high quality, resulting in irregular results and consumer discontentment. The visibility of foam can hinder the appropriate mix of materials, leading to problems such as air pockets, irregular textures, or instability in final product. These issues not only impact the aesthetic appeal but can also impact the practical performance of the product.

Carrying out anti-foam control solutions efficiently reduces foam formation, ensuring an uniform product consistency. By preserving the preferred viscosity and stability of materials during processing, manufacturers can achieve better outcomes. This enhancement in item high quality equates into boosted integrity and contentment for end-users, promoting brand commitment and a solid market presence.

Additionally, advanced anti-foam representatives can be customized to specific manufacturing procedures, ensuring optimal efficiency without adversely affecting other buildings of the solution. By incorporating these solutions, manufacturers can promote stringent quality standards while reducing the risk of product recalls or remodel, which are damaging and frequently costly to online reputation.

Cost Decrease Approaches

Applying efficient anti-foam control solutions not just boosts product quality but also substantially adds to cost reduction methods in manufacturing. By minimizing foam formation, manufacturers can lower waste linked with spills and overflows, which typically result in item loss and enhanced operational prices. This not only maintains basic materials yet likewise streamlines manufacturing procedures, ultimately bring about greater performance.

Additionally, consistent foam control can boost process stability, investigate this site decreasing the probability of manufacturing downtimes brought on by foam-related interruptions - Anti-Foam Control Solutions. By achieving smoother procedures, producers can maximize their throughput, leading to boosted overall productivity and success

Furthermore, with reduced demand for extra ingredients and lower energy usage during manufacturing, business can further realize significant savings. Spending in anti-foam control services stands out as a critical method to accomplishing comprehensive expense decreases in manufacturing settings.

Enhanced Equipment Longevity

Reliable anti-foam control solutions play an essential function in expanding the longevity of production devices. Excessive foam accumulation in manufacturing processes can cause substantial damage on machinery, as well as practical inadequacies. When foam builds up, it can obstruct circulation courses, causing pumps and other tools to function more difficult than essential, which increases mechanical deterioration.

Additionally, frothing can result in deterioration, particularly in fluid systems where foam catches chemical representatives that might be harmful to tools surfaces. By carrying out anti-foam control remedies, suppliers can minimize these threats, making certain smoother procedures and minimizing the regularity of upkeep and fixings.

Better Compliance and Safety

Boosted compliance and security requirements in making processes are substantially affected by the combination of anti-foam control options. These remedies successfully reduce the threats connected with foam development, which can result in harmful problems, such as spills or equipment breakdowns. By controlling foam, manufacturers can maintain a safer working setting, decreasing the chance of accidents that may cause injuries or damage to tools.

In addition, regulatory compliance is crucial in the manufacturing market. Anti-foam agents play an important duty in adhering to market criteria and ecological laws. By minimizing foam-related discharges and effluents, business can demonstrate their commitment to environmental stewardship while staying clear of possible penalties and legal repercussions.

In addition, reliable foam control improves process performance, enabling constant product quality and reduced waste. This not just meets consumer assumptions but also straightens with the very best techniques outlined by governing bodies.

Verdict

The application of anti-foam control remedies in making processes returns substantial benefits, including boosted production effectiveness, improved product top quality, and significant price reductions. These options not just lessen foam development however likewise add to enhanced tools long life and conformity with security and environmental laws. By dealing with these essential locations, manufacturers can achieve higher functional excellence and profitability, inevitably promoting an extra lasting and effective production setting.

In turn, this adds to far better source management and expense financial savings, enhancing the relevance of spending in reliable foam control strategies as a way to enhance manufacturing efficiency in manufacturing setups.

Applying anti-foam control remedies efficiently minimizes foam formation, making certain an uniform product consistency. These remedies successfully reduce the risks linked with foam development, Click This Link which can lead to harmful problems, such as spills or equipment breakdowns. By regulating foam, suppliers can keep a more secure working setting, reducing the possibility of mishaps that may result in injuries or damages to tools.

These solutions not just reduce foam development however additionally add to boosted equipment durability and conformity with security and environmental regulations. Anti-Foam Control Solutions.